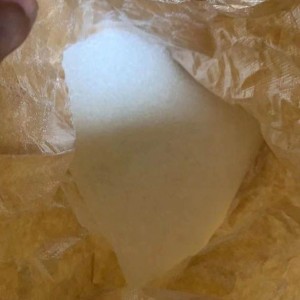

Marka la doorto monomers gaar ah, qofku wuxuu gaari karaa polyamide crystallizable oo joogto ah oo hufan. Crystallites aad bay u yar yihiin oo ma kala firdhiyaan iftiinka muuqda, maaddaduna waxay u muuqataa mid hufan oo isha aadanaha ah - hanti loo yaqaan microcry stallinity. Sababtoo ah crystallinity, qaab-dhismeedka microcrystalline wuxuu hayaa sifooyin muhiim ah sida iska caabin dildilaaca - iyada oo aan daruur lahayn. Si kastaba ha ahaatee, heerka crystallinity waa mid aad u dayacan, si kastaba ha ahaatee, in aysan saameyn xun ku yeelan habdhaqanka yaraanta qaybaha la qaabeeyey. Waxay maraysaa hoos u dhac isotropic oo la mid ah sida walxaha amorphous.

Waa polyamide-ka-muuqaalka hoose ee daah-furnaanta joogtada ah ee qaabaynta duritaanka.